What are the common testing items for electronic components?

Date:2024-08-22 15:00:00 Views:145

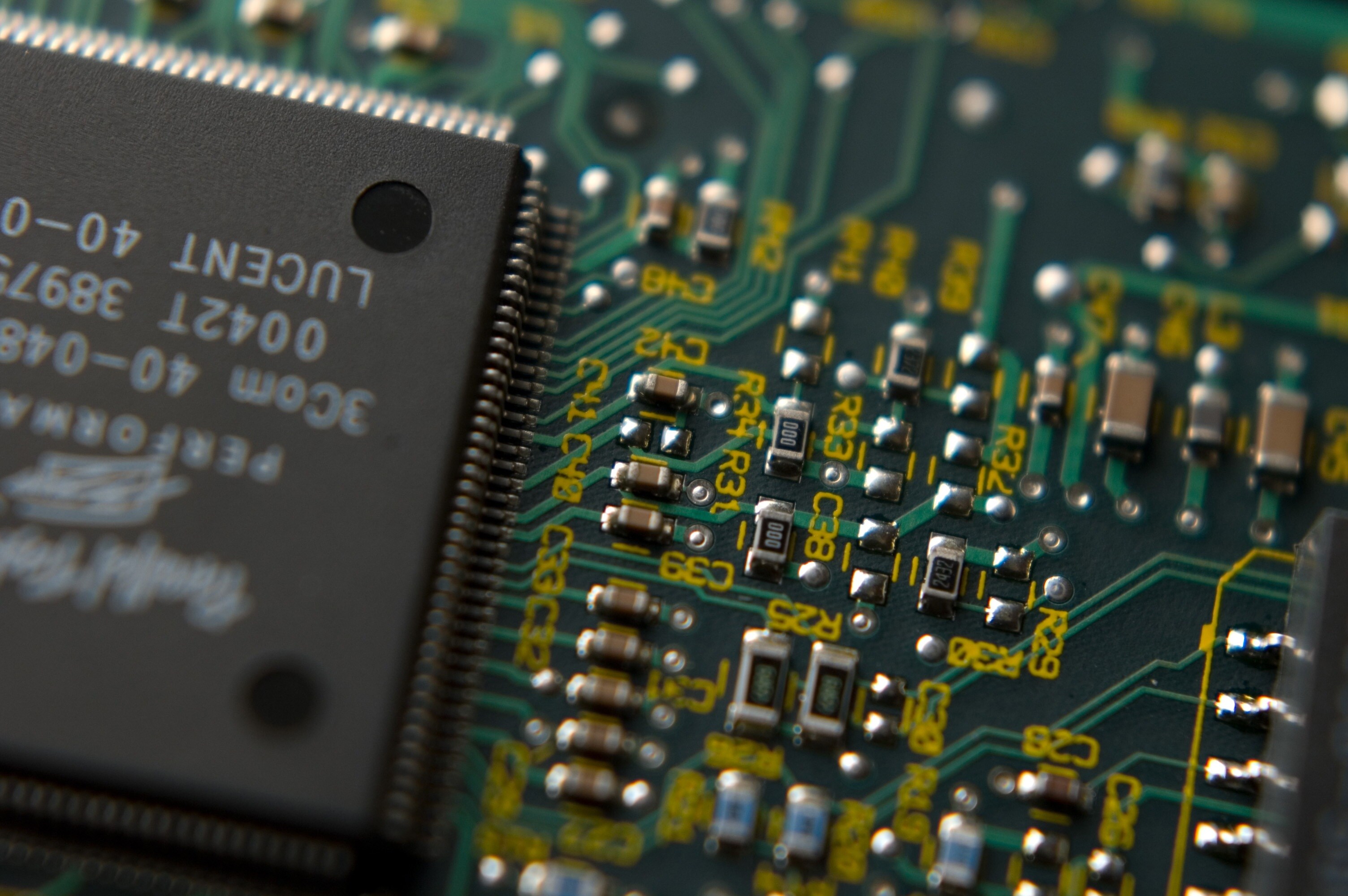

Electronic componentsThe testing project usually includes multiple aspects to ensure its performance, reliability, and compliance with specification requirements. The following are common testing items:

1. Appearance inspection

· Check the physical appearance of the components and look for any obvious defects, damage, or contamination.

2. Electrical performance testing

· DC parameter testingMeasure basic electrical parameters such as resistance, current, and voltage.

· Communication parameter testingMeasure AC voltage, frequency, phase, etc.

3. functional testing

· Ensure that the components can operate normally under their specified working conditions and meet functional requirements.

4. Voltage withstand test

· Test the voltage endurance of components under conditions higher than normal operating voltage to ensure that they will not fail under extreme conditions.

5. Temperature testing

· Test the performance of components at different temperatures and evaluate their stability in high or low temperature environments.

6. Aging test

· Test components under accelerated aging conditions such as high temperature and high humidity to evaluate their long-term reliability.

7. Frequency response test

· Measuring the response of components at different frequencies is particularly suitable for frequency related components such as filters and amplifiers.

8. Load testing

· Test the performance of components under different load conditions to ensure their stability in practical applications.

9. Short circuit and open circuit tests

· Check for short circuits or open circuits in the circuit to ensure its integrity.

10. Hot testing

· Use thermal imagers or thermocouples to monitor the operating temperature of components and identify potential overheating issues.

11. Electromagnetic compatibility(EMC testing

· Test the performance of components in terms of electromagnetic interference and radiation to ensure compliance with relevant standards.

12. Electrostatic discharge(ESD testing

· Test the tolerance of components to electrostatic discharge to evaluate their reliability in electrostatic environments.

13. Material analysis

· Analyze the component materials to ensure that their composition and structure meet the design requirements.

14. failure analysis

· When a failure occurs, conduct a detailed failure analysis to identify the cause and mode of the failure.

summary

Through comprehensive testing projects, the performance and reliability of electronic components can be ensured under various conditions, meeting design and application requirements.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou